Using Dye Sublimation Printing to Create Beautiful Products

Have you ever wondered how some regularly used products have appealing prints that never seem to fade away? It is not some magical secret, but a very interesting and effective technique that plays a role here. That technique is called Dye Sublimation Printing.

What is Dye Sublimation Printing?

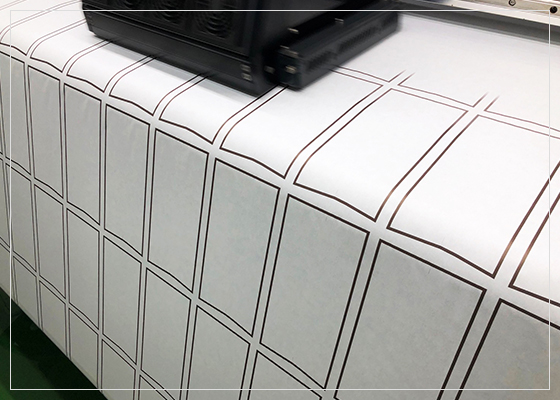

The principle of dye sublimation transfer refers to the fact that when the heat sublimation ink is heated to a specific temperature, the dye will sublimate from a solid state to a gaseous state, and when the temperature drops, the dye will return to a solid state, and then the dye can penetrate into the surface of the transferred fabric to achieve the transfer effect.

The technique is so effective that the colors or prints do not fade away or crack after multiple times of washing. The finish is smooth and soft as the print gets embedded into the fabric.

Moreover, dye sublimation printing allows for more creative, intricate, and unique designs.

| Advantage | Disadvantages |

|---|---|

| High air permeability, good color fastness, and high color saturation. | Not applicable to cotton fabric, not transferable on dark fabric |

Dye-sublimation printing of fabrics used to be an expensive technique due to the multi-step process and the equipment involved. With technological advancements, simpler and more cost-effective equipment has made the process pocket friendly.

What is the difference between traditional screen printing and dye sublimation printing?

Traditional Screen Printing: After the printer confirms the file, the file will be divided into colors and screened according to CMYK, this step is called "color separation".

Dye sublimation printing: This is the general output center of the printing machine, this printing method does not need to go through the plate production, only the design layout file output data is printed out, and most of them are used for small, fast, and diverse printing.

Comparison of differences:

| Traditional Screen Printing |

Digital Sublimation Printing | |

|---|---|---|

| Manpower | 2-3 persons are needed for complicated work process | Only one operator is required to operate the computer equipment |

| Time | Washing and drying plates after printing are time-consuming | Can be operated at any time without any time limit |

| Land occupation | Because of the lengthy process of the machine, a larger space is needed | Only need to set up the equipment factory and design and operation office |

| Cost | Need to open plates for printing, if a small amount, it will increase the printing cost per unit | Can be customized according to different needs, at a relatively lower cost than screen printing |